Introduction

We are always ready to transform your ideas into reality and provide modern manufacturing solutions fit for your products, from design to prototyping to production.

CUSTOMIZED FOR YOU

Our Services Of Rapid Prototyping & Manufacturing

Content:

We offer one-stop rapid prototyping and cost-effective rapid manufacturing services at Hove Studio to assist every stage of your product development and help you get to market faster. Do you require 1 or 10,000 units? Production-quality materials? Geometric shapes that are complex? Tolerance issues? Fine points? We will always do our utmost to accommodate your design and manufacturing requirements. Our objective is to make your ideas a reality.

CNC machining

CNC machining is an excellent choice for custom machined prototypes and production parts that must meet stringent requirements such as exact tolerances, special materials, complicated parts, and maximum efficiency.

CNC Aluminum Milling

Advanced 3- and 5-axis CNC milling, turning in conjunction with auxiliary processes EDM and wire EDM, as well as standard aluminum surface finishing, can achieve the most efficiently precise CNC aluminum machining process.

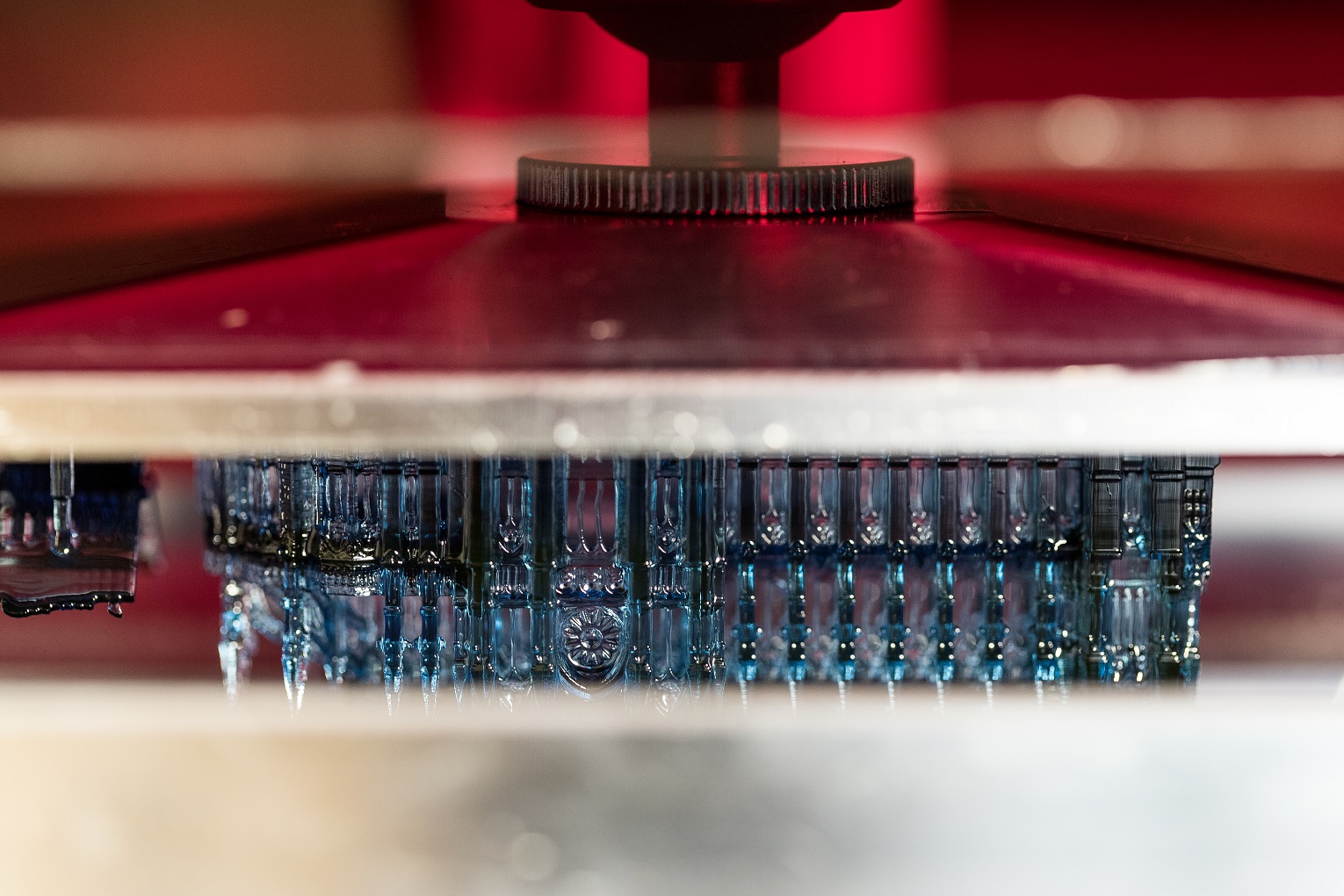

3D Printing

To deliver fast and accurate rapid prototypes, we have two USA 3D system SLA machines, SLA5000 and SLA7000.

Vacuum Casting

Vacuum casting (or urethane casting) is a quick approach to create a small batch of functional plastic prototypes, producing end-use, stiff, flexible, and rubber parts at a cheap cost and production-grade quality.

Rapid Tooling Services

Rapid tooling is also known as prototype tooling, bridge tooling, and soft tooling. Rapid tooling is a critical phase in the production process. Tooling, according to its definition, refers to manufacturing utilized to make products such as rapid injection molds, rapid die-cast molds, sheet metal prototype molds, quick and easy jigs and fixtures, and other bespoke tooling parts. Rapid tooling for trial production of hundreds or even thousands of pieces prior to mass production is a very useful stage for design optimization, functional testing, or pre-production verification.

Rapid Sheet Metal Prototype

We created high-quality sheet metal prototypes as well as short-run production. Sheet metal skills include sophisticated metal forming, shearing, CNC bending, CNC punching, CNC laser cutting, Wire EDM, and welding. Drilling, tapping, counterboring, and countersinking are common processes for sheet metal parts, as is surface finishing such as plating, polishing, hairline, and sanding brushing.

Enquiry

Every successful decision begins with Enquiry

After receiving the inquiry, we will call you back during office hours.